Experimental Work

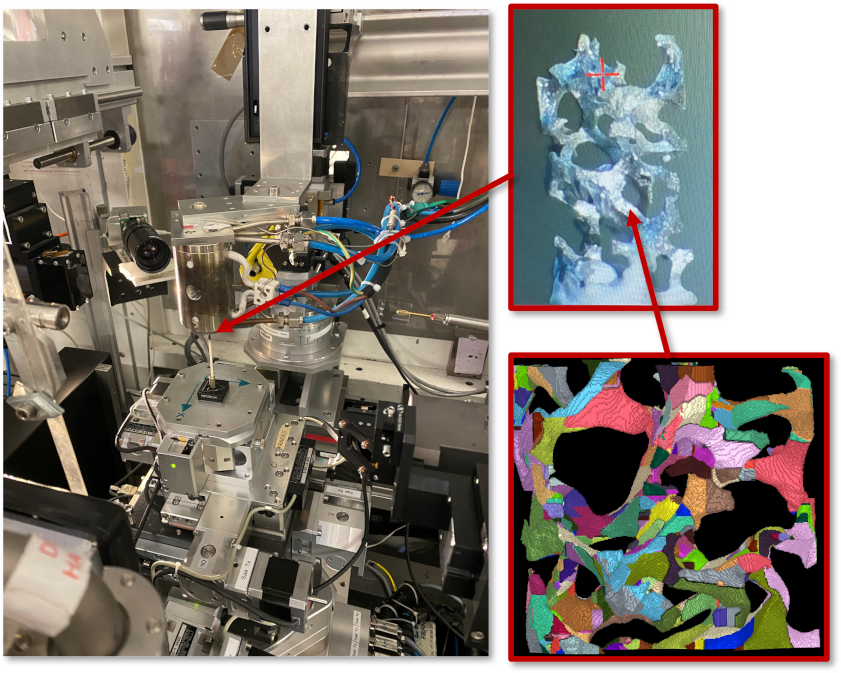

Synchrotron-based tomography and diffraction as well as more conventional materials characterization techniques, combined with numerical simulations.

References

Further details on experimental work and modeling and simulation on materials processing can be found in:

- I. Tambe, J.E. Maroti, I.N. Orbulov, Z. Hegedus, M. Ziehmer, C.E. Krill III, H. Hallberg, P.A.T. Olsson and J. Hektor, X-Ray Tomography Analysis of Damage Mechanisms in Metal Matrix Syntactic Foams During Compression, Advanced Engineering Materials

- H. Hallberg, A. Chamanfar and N. Nanninga, A constitutive model for the flow stress behavior and microstructure evolution in aluminum alloys under hot working conditions - with application to AA6099, Applied Mathematical Modelling, 81C:253-262, 2020

- S. Pettersson, J. Engqvist, S. Hall, N. Toft and H. Hallberg, Peel testing of a packaging material laminate studied by in-situ X-ray tomography and cohesive zone modeling, International Journal of Adhesion and Adhesives, 95:102428, 2019

- J. Hektor, J.-B. Marijon, M. Ristinmaa, S.A. Hall, H. Hallberg, S. Iyengar, J.-S. Micha, O. Robach and O. Castelnau, Evidence of 3D strain gradients associated with tin whisker growth, Scripta Materialia, 144:1-4, 2018

- H. Hallberg, F. Adamski, S. Baiz and O. Castelnau, Microstructure and property modifications of cold rolled IF steel by local laser annealing, Metallurgical and Materials Transactions A, 48(10):4786-4802, 2017